NEW LPA MAINTENANCE FACILITY PROVING ITS WORTH

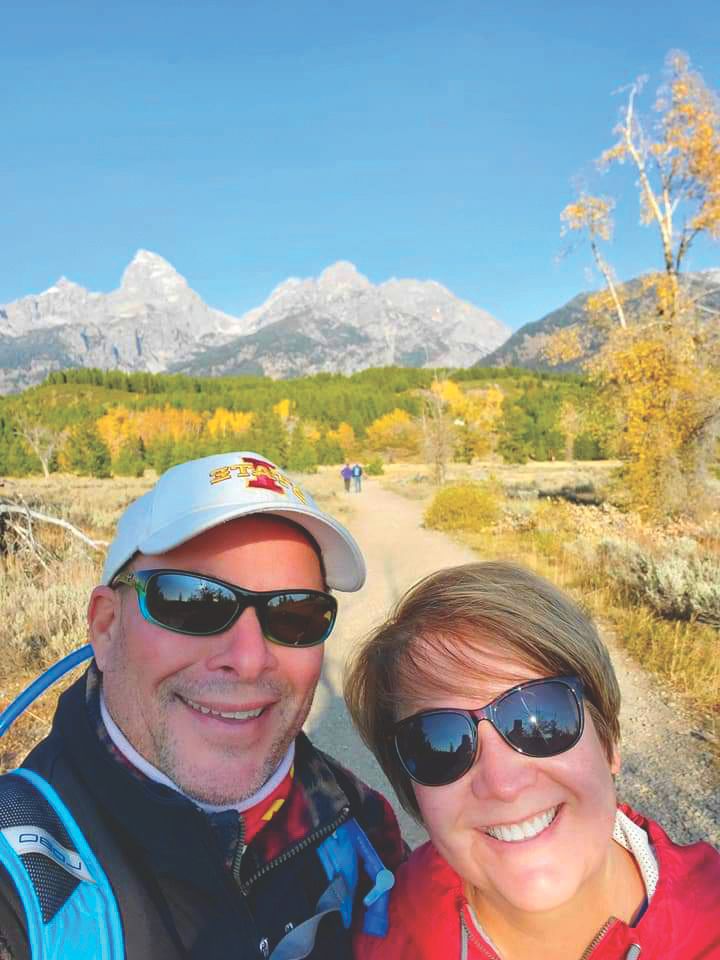

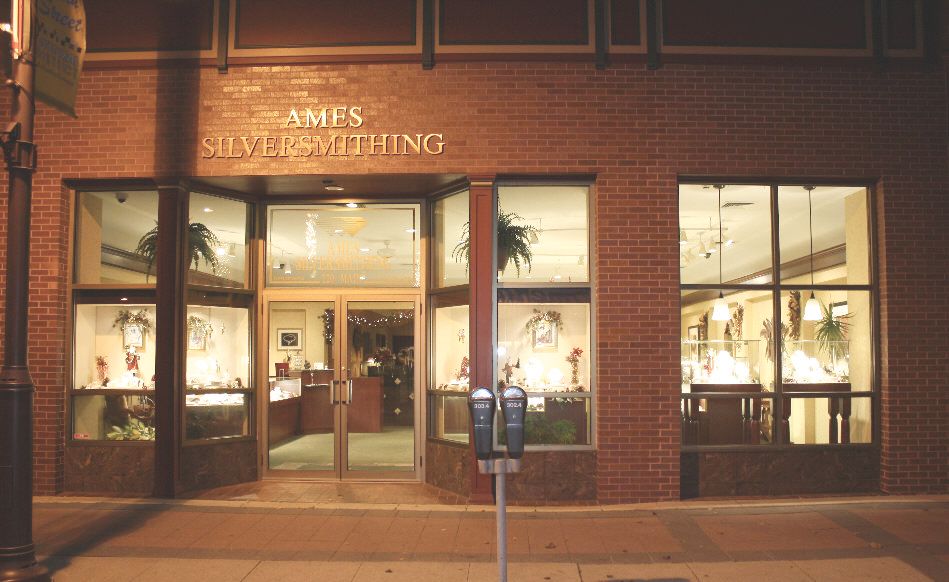

The 10,000-square-foot shop is the main building at the new site.

Posted 3/9/21

By Susan Thompson

Lake Panorama Times

This winter has been the first full season the new LPA maintenance facility has been available to staff. And to say the facility is working as planned would be an understatement.

“The 2019 maintenance facility is proving to be an excellent infrastructure investment for the association,” says John Rutledge, LPA general manager. “Although it has only been 15 months since we moved in, it is difficult to recall how we functioned without this facility. The shop provides our crew the opportunity to repair and maintain essential equipment, which has been especially critical during the heavy snowfall winter of 2020-21.”

This project first was introduced to the LPA board in the fall of 2014. It was the fall of 2018 before plans were completed, a location was chosen, and construction began.

Move-in began in mid-October of 2019, and 200 people attended an open house Nov. 22, 2019. But it was a few months into 2020 before the move was complete and all shelving and cabinets had been assembled and installed by LPA staff.

The new maintenance complex, located on the lake’s east side at the corner of 200th and Chimra, includes a shop that measures about 10,000 square feet. Also on the site is a cold storage building that has a crushed rock floor. It is used for storing items that don’t need to be kept in a heated environment.

There are two large hoop structures, one for salt and one for sand storage. A smaller hoop structure is a dedicated space for mixing brine, which is used on Lake Panorama roads in the winter. This keeps this process out of the shop, since brine is corrosive. Also at the site are storage bins for aggregate and other materials.

The facility replaced the old maintenance facility located a quarter-mile further west that was built in 1973. It was 4,000 square feet and didn’t come close to providing the needed space for the maintenance equipment and employees that now support the Lake Panorama community.

In addition, signs of corrosion were discovered in late 2016, and the building was temporarily modified in the fall of 2018 to support LPA operations that winter. The LPA board confirmed staff and engineer recommendations that LPA crews not spend another winter in that facility.

Mike Monthei, LPA operations supervisor, manages the facility.

“Being able to repair equipment in a clean and controlled environment helps to keep our equipment in good order,” Monthei says. “This is not only important from a productivity standpoint, but also from a worker safety standpoint.”

The new shop provides a heated space for storage and maintenance of key pieces of LPA equipment. Large overhead doors on both sides of the building allow trucks and trailers to be pulled through the building. A lift in the southeast corner makes it easy to perform routine maintenance on vehicles.

In addition to serving the LPA maintenance department, the facility houses equipment that serves the LPA security, water and erosion control departments.

An earthen berm was built to the west and south of the facility. On top and outside of this berm are evergreen plantings that provide a visual screen. Cupolas, wainscot and a stone entrance to the shop’s office area all “dress up” the facility.

The maintenance complex cost was $1.7 million. LPA worked with a consortium of local banks to finance the project with payoff structured as a 20-year loan.

The cold storage building located at the old maintenance facility site was repurposed for boat storage, beginning last fall. The old shop was torn down in early 2020.

“On behalf of the Lake Panorama staff, I want to thank the LPA board and membership for their support of this important project,” says Rutledge. “This facility will help our team continue to provide top-notch service to the LPA membership for decades to come.”

By Susan Thompson

Lake Panorama Times

This winter has been the first full season the new LPA maintenance facility has been available to staff. And to say the facility is working as planned would be an understatement.

“The 2019 maintenance facility is proving to be an excellent infrastructure investment for the association,” says John Rutledge, LPA general manager. “Although it has only been 15 months since we moved in, it is difficult to recall how we functioned without this facility. The shop provides our crew the opportunity to repair and maintain essential equipment, which has been especially critical during the heavy snowfall winter of 2020-21.”

This project first was introduced to the LPA board in the fall of 2014. It was the fall of 2018 before plans were completed, a location was chosen, and construction began.

Move-in began in mid-October of 2019, and 200 people attended an open house Nov. 22, 2019. But it was a few months into 2020 before the move was complete and all shelving and cabinets had been assembled and installed by LPA staff.

The new maintenance complex, located on the lake’s east side at the corner of 200th and Chimra, includes a shop that measures about 10,000 square feet. Also on the site is a cold storage building that has a crushed rock floor. It is used for storing items that don’t need to be kept in a heated environment.

There are two large hoop structures, one for salt and one for sand storage. A smaller hoop structure is a dedicated space for mixing brine, which is used on Lake Panorama roads in the winter. This keeps this process out of the shop, since brine is corrosive. Also at the site are storage bins for aggregate and other materials.

The facility replaced the old maintenance facility located a quarter-mile further west that was built in 1973. It was 4,000 square feet and didn’t come close to providing the needed space for the maintenance equipment and employees that now support the Lake Panorama community.

In addition, signs of corrosion were discovered in late 2016, and the building was temporarily modified in the fall of 2018 to support LPA operations that winter. The LPA board confirmed staff and engineer recommendations that LPA crews not spend another winter in that facility.

Mike Monthei, LPA operations supervisor, manages the facility.

“Being able to repair equipment in a clean and controlled environment helps to keep our equipment in good order,” Monthei says. “This is not only important from a productivity standpoint, but also from a worker safety standpoint.”

The new shop provides a heated space for storage and maintenance of key pieces of LPA equipment. Large overhead doors on both sides of the building allow trucks and trailers to be pulled through the building. A lift in the southeast corner makes it easy to perform routine maintenance on vehicles.

In addition to serving the LPA maintenance department, the facility houses equipment that serves the LPA security, water and erosion control departments.

An earthen berm was built to the west and south of the facility. On top and outside of this berm are evergreen plantings that provide a visual screen. Cupolas, wainscot and a stone entrance to the shop’s office area all “dress up” the facility.

The maintenance complex cost was $1.7 million. LPA worked with a consortium of local banks to finance the project with payoff structured as a 20-year loan.

The cold storage building located at the old maintenance facility site was repurposed for boat storage, beginning last fall. The old shop was torn down in early 2020.

“On behalf of the Lake Panorama staff, I want to thank the LPA board and membership for their support of this important project,” says Rutledge. “This facility will help our team continue to provide top-notch service to the LPA membership for decades to come.”

The 10,000-square-foot shop is the main building at the new maintenance site. During the winter months, the heated building houses several vehicles overnight. This includes the five LPA trucks with snowblades that are kept loaded with sand and salt, ready to clear roads as needed. Picnic tables from the beaches that need stained or repaired are brought to the shop in the fall and worked on as time permits.